Phone Box - American Express®

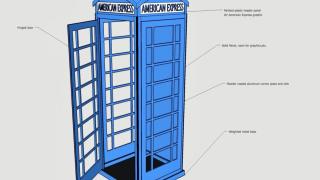

We were commissioned to create classic British phone boxes in a deep shade of blue, a signature color for the Blue from American Express® campaign. The phone booths would be shipped to cities like London, Mumbai and New York where they would be outfitted with iPads to help the company promote the user experience of a new app.

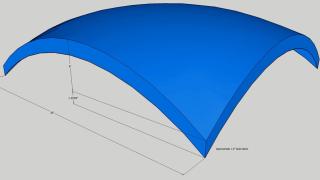

We went back and forth with the client discussing the various historical iterations of the phone box: we looked at the window mullions, the style of the dome and the base, ultimately settling on the K6 booth, originally designed in 1935 to commemorate the silver jubilee of King George V.

Known as the “jubilee” kiosk, it was number six in the line of telephone box designs that began in 1920 (K1 was made from concrete, clearly not practical for this project!). K6 was the first British phone box to be used extensively throughout the countryside and was designed in pieces to be transported.

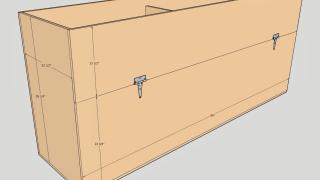

Our replica of the iconic British phone booth needed to be sturdy enough to accommodate a steady flow of visitors while light enough in weight to be shipped around the world. We had to create a structure that could be easily assembled by a trade show crew and later taken apart and packed in a custom shipping crate.

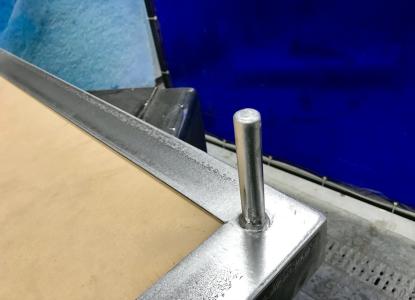

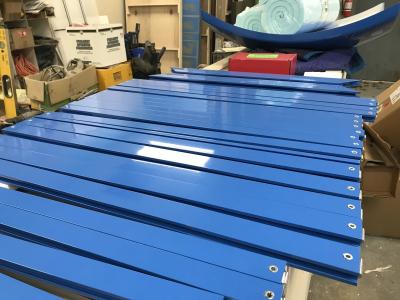

We had the aluminum frame pieces custom manufactured in interlocking parts similar to an erector set so the booth could be easily assembled. We partnered with a plastics manufacturing company, sending them a CAD file with the specs so they could cast a solid PVC dome that could be affixed to the top of the structure.

Painting proved to be the biggest challenge, since the three main materials–aluminum, wood and plastic–would each hold paint in a completely different manner. We had to create three different paint formulas so the overall glossy finish would be a consistent shade of blue. This was a complicated process that involved concocting a powder coat to paint the aluminum and the blue lacquer on the dome.

The five phone boxes created so far have been a success, crisscrossing the globe with visits to London, New York, Phoenix, Salt Lake City, Manila, New Delhi, Mexico City and more. They are also durable. The only repairs we’ve had to make has been to a single shipping crate lid. Indeed, we would rather repair the crate than the contents!